Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Why standardizing makes sense

Advanced manufacturing thrives when shops can share workloads easily, automate frequent process steps, and simplify management of complex processes.

The power of one

Standardization helps address your most urgent needs as shops transition to agile operations that can adapt to industry and market changes more easily.

-

Address Skills Gap

Capture and share best practices across your manufacturing teams.

-

Process Efficiency

Replace stand-alone processes that result in fragmented workflows.

-

Automation

Use fully integrated systems to eliminate redundancy.

-

Simplification

Streamline training, support, and management.

Design and manufacturing workflows in action

See examples of how standardizing on Autodesk advanced manufacturing software leads to gains in efficiency, innovation, and automation.

-

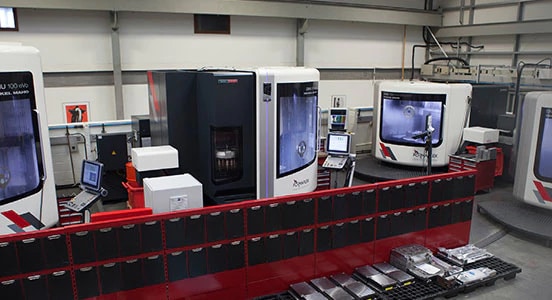

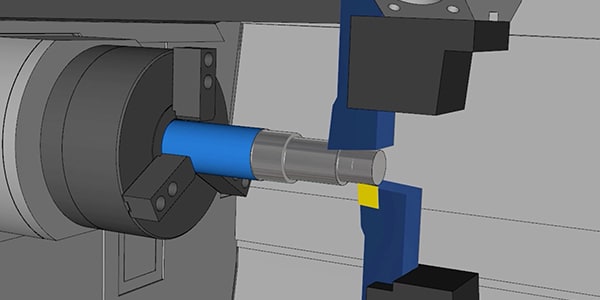

Production Machining

Use automation to simplify part programming, drive consistency, and allow easier implementation of complex machining processes.

-

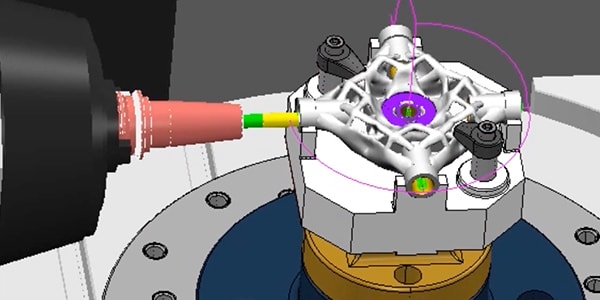

Generative Design

Explore unlimited design iterations using goals and parameters such as materials, loads, manufacturing methods, and cost constraints.

-

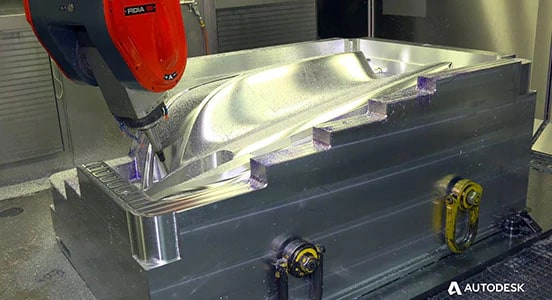

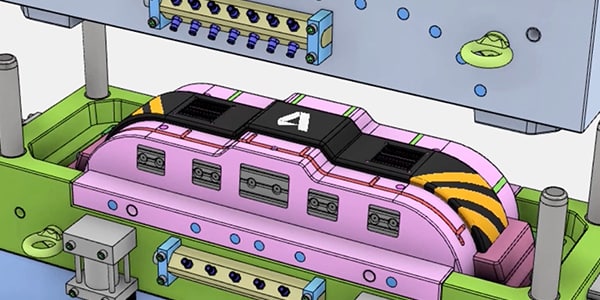

Mold Production

Discover plastic part quality issues and molding defects during the design stage before tooling goes into production, thereby saving costs.

-

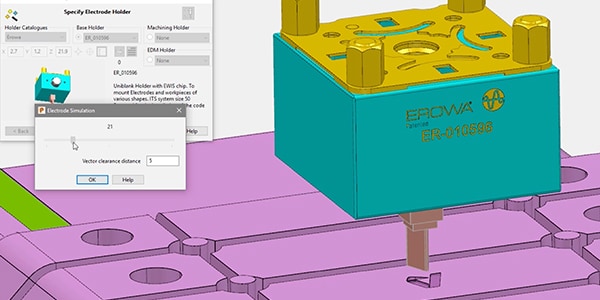

Electrode Manufacture

Use automated wizards, pre-defined machining strategies, movement simulation, and easy data sharing to maximize the efficiency electrodes.

Try advanced manufacturing products - free for 30 days

Experience the advantages of standardization with 30-day free trials of our advanced manufacturing software.

PowerShape

Modeling software to prepare molds, dies, and other complex parts for manufacture

Let's talk

Choosing a single software provider for advanced manufacturing is a big decision that can deliver huge benefits. Autodesk has all of the tools you need, and we have a team of advanced manufacturing specialists ready to learn about your business and see how we can help.

Call 1-855-612-9998 (toll-free in US).

Call us Monday to Friday, 9am to 5pm or fill in the form and one of our experts will contact you.