Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

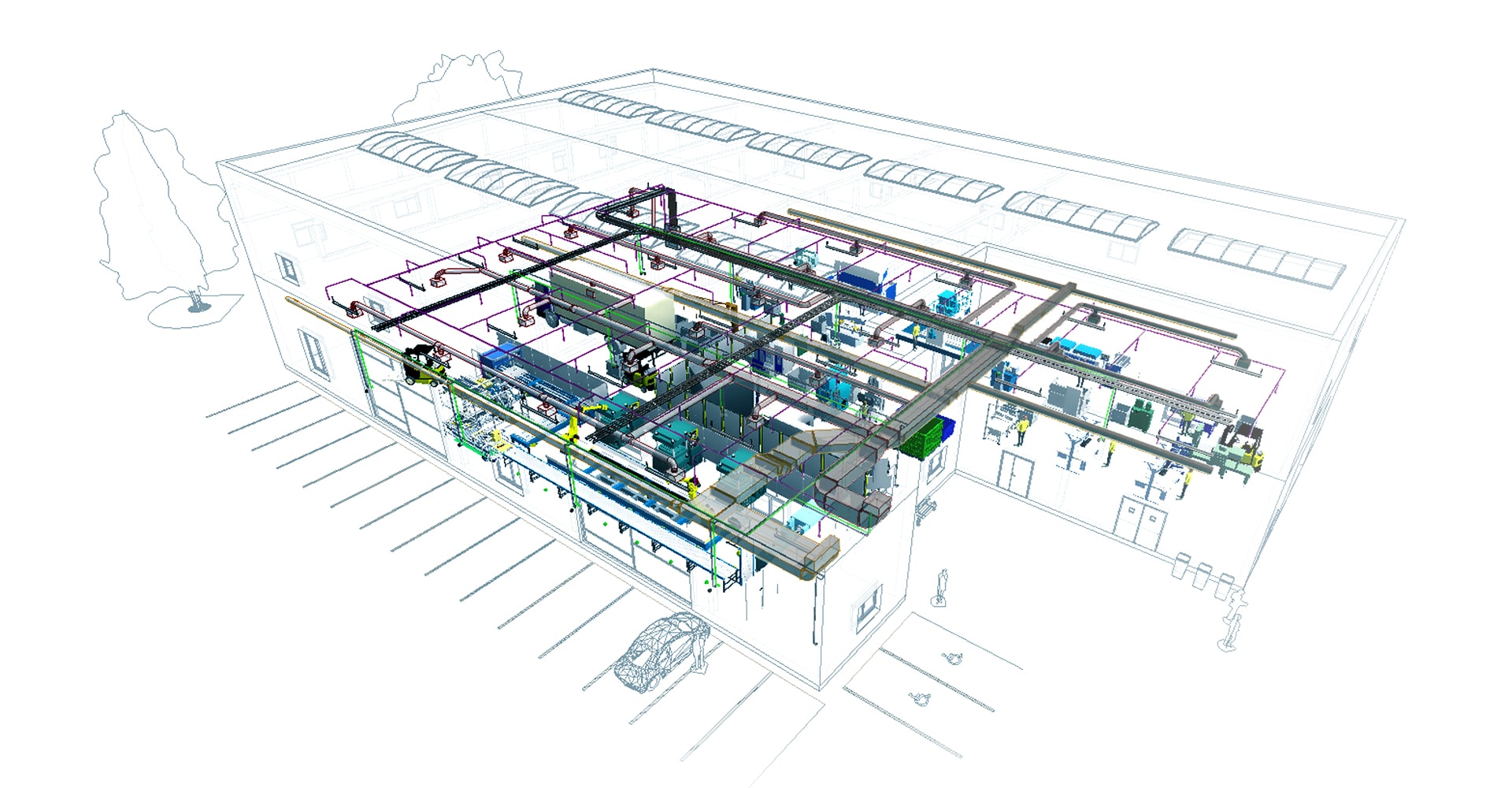

One shared model for your production and facility teams

Make more informed decisions by coordinating efforts across different functions with a single digital model. Integrate equipment, production line layouts, Building Information Models (BIM), and reality capture data originating from different design systems.

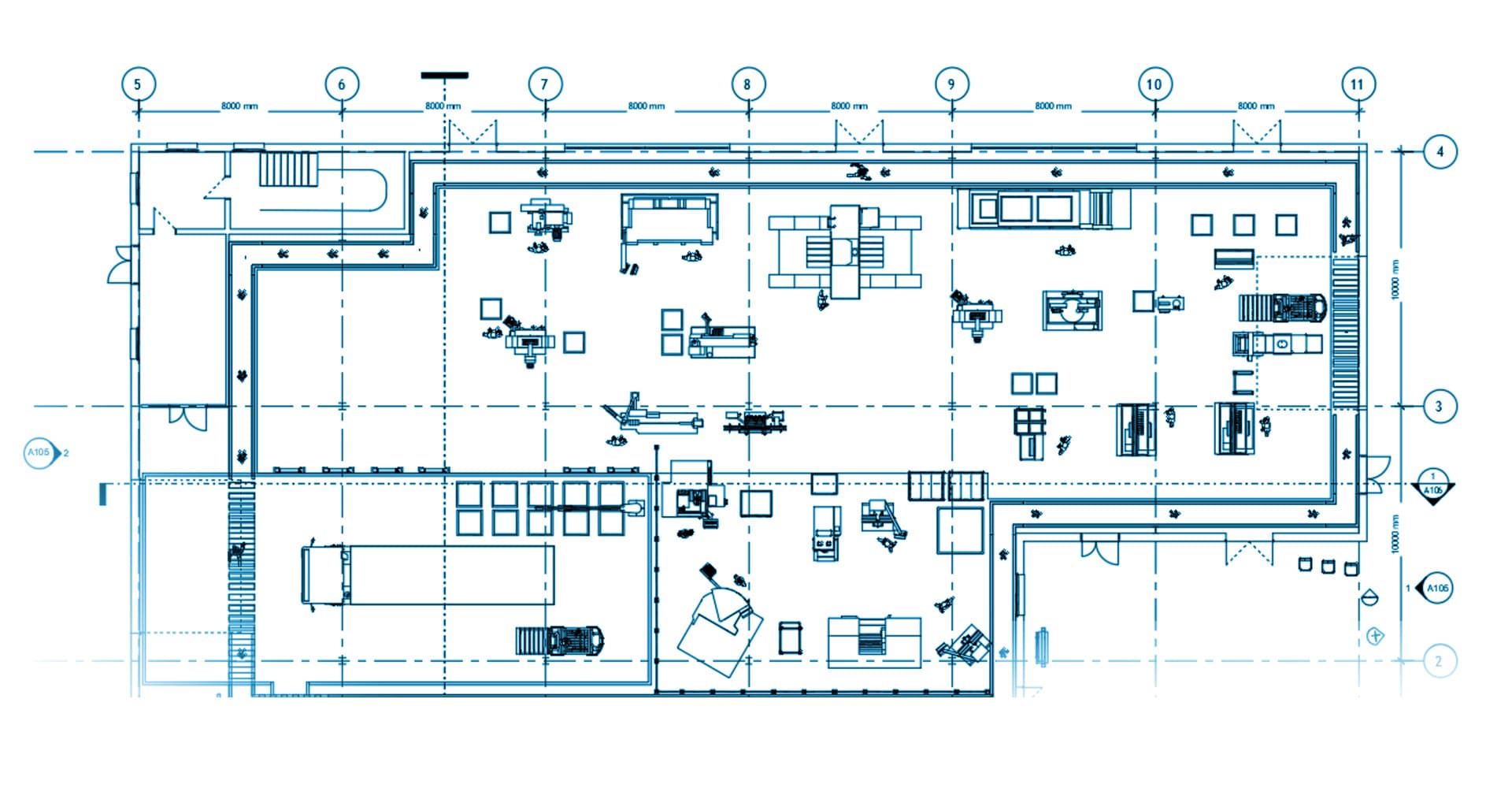

Smarter and faster production line layout

Easily conceptualize production line layouts using familiar 2D workflows to automatically convert 2D layouts into detailed 3D models, providing that extra dimension to inform critical design decisions.

Experience the value of BIM

Integrate architectural, MEP, and structural designs into a multidisciplinary building information model of your facility, accessible by all stakeholders to manage your project on time and on budget. Whether it’s a new building or a retrofit, BIM helps optimize the energy efficiency of your factory and lower your operating costs.

Accurately capture the as-is state

Quickly capture the state of your facility with laser scanning when existing drawings or models are unavailable. Accurately measure, markup, and run clash detections between the resulting point cloud with the proposed production line design.

Maintain a library of configurable equipment assets

Make up-to-date equipment models available for ongoing production planning and layout by authoring configurable factory assets. Publish assets locally for internal teams or upload to the cloud to give access to contributors outside your firewall.

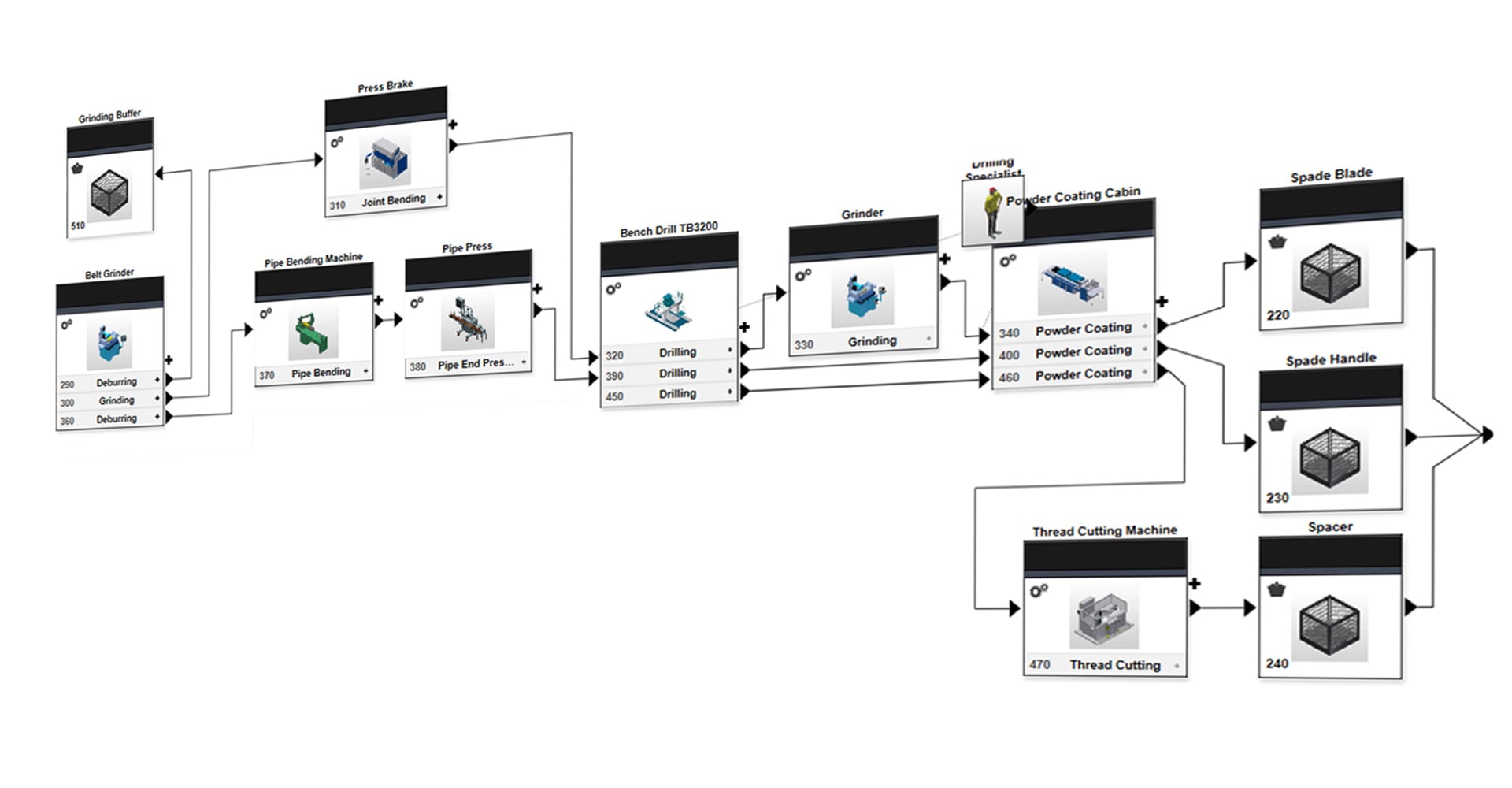

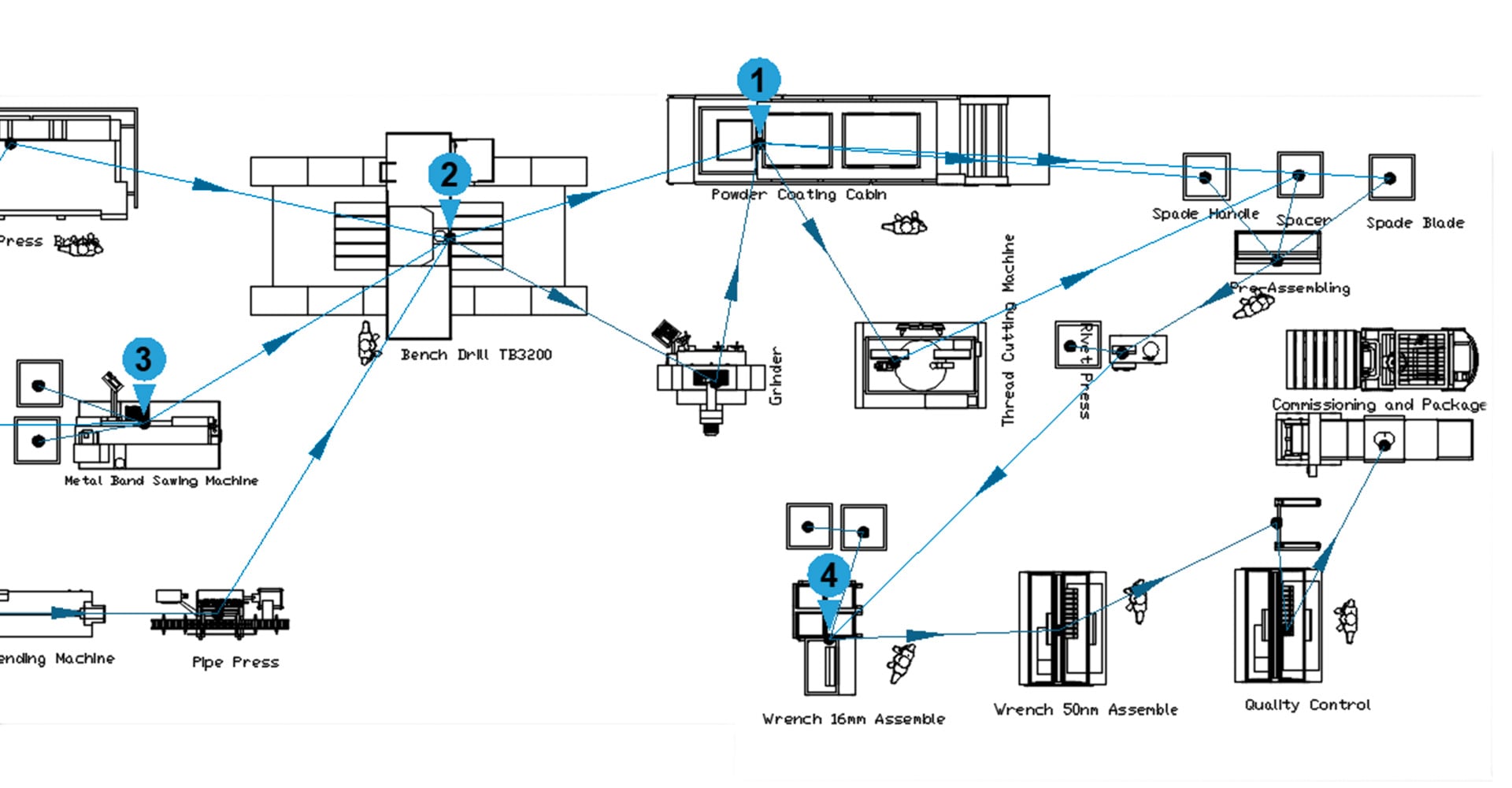

Plan for production efficiency

Improve manufacturing efficiency, identify bottlenecks and maximize the number of components that can be produced in a specified period by modeling, studying, and optimizing your production line concept.

Find just the right material flow

Analyze your layout for efficient material flow early in the design process by identifying where non-value-added costs are incurred while transporting material within the factory.

Explore digital factory resources

Download the white paper or watch an on-demand webinar to see how digital factory tools can help you adapt to changes quickly while becoming more efficient.

Combining BIM & Production Line Design

Manufacturing owners manage an ongoing schedule of projects to build, update, and improve facilities. Explore a new approach to production planning that leverages industry leading technology and collaboration.

Best Practices for a Flexible Factory

Production is in a constant state of change. These changes often cause significant problems for manufacturers. Learn how to tackle your most pervasive change-related challenges with digital factory tools.