Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Watch: compare automated vs traditional CNC setup (1:49 min.)

Why automated setup makes sense

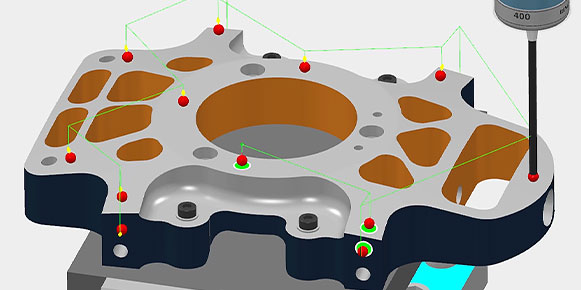

Replace your manual, time-consuming workpiece setup with quick, accurate, and repeatable automated part setup to increase CNC milling machine utilization and achieve significant productivity improvements. Automated setup enables you to meet production goals and avoid expensive rework for a fast return on investment in your machines and software. Maximize your existing investments in your high-value CNC machinery and defer capital for future equipment purchases.

CNC automation helps with productivity

Short intro. Excepteur sint occaecat cupidatat non proident, in culpa qui officia.

WIN MORE BUSINESS

Expand your capacity by maximizing CNC machine utilization and your ROI.

INCREASE EFFICIENCY

Replace the highly skilled, traditional time-consuming manual machine setup with automated machine setup.

PEACE OF MIND

Begin machining quicker with the confidence that workpieces are accurately setup.

IMPROVE QUALITY

Beyond automated part setup you can verify manufacturing part quality at the earliest opportunity.

Save more time with on-machine verification

Go beyond automated setup with on-machine verification (OMV) to achieve an even faster ROI. Gain significant throughput improvements by further optimizing machine utilization with in-cycle probing that allows you to make informed decisions quickly to avoid scrap or rework. Remove bottlenecks in your manufacturing process by only sending parts to your quality department for final inspection.

Automated setup workflows

-

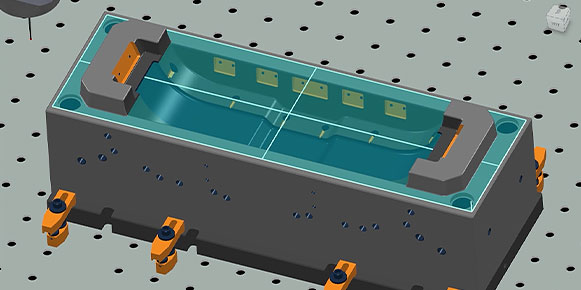

POWERMILL AND POWERINSPECT

Achieve quick, accurate, and consistent setups, and verify part accuracy to maximize your CNC investments.

-

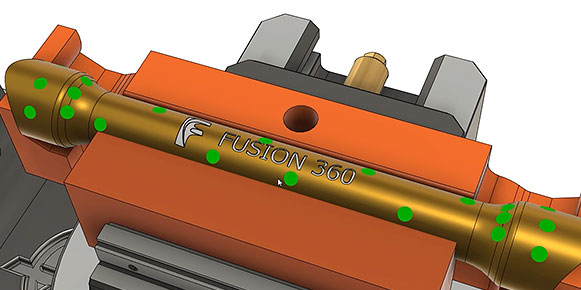

FUSION 360 MACHINING EXTENSION

Integrate design, manufacturing, part setup, and verification to realize the full potential of your CNC milling machines.

-

FEATURECAM AND POWERINSPECT

Minimize lost time setting up parts with quick, accurate and consistent setups to maximize the profitability of your machining programs.

Ready to take your business to the next level?

For automated setup and in-process measurement on your CNC milling machines you can choose from these products.

Let’s talk

Every manufacturing facility wants to remove non-productive operations. Alongside the highest quality implementation and technical support, our team of advanced manufacturing specialists is ready to help you realize the full potential of your CNC milling machines.

Call 1-855-612-9998 (toll-free in US)

Call us Monday through Friday, 9 a.m. to 5 p.m. or fill in the form and one of our experts will contact you.

Thank you for your interest.