Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Project Overview

The section of the A10/A24 Havelland Autobahn is an important and busy trans-European transportation axis. Built by the German Democratic Republic in the 1970s, this stretch of road has aged and will be renovated over multiple stages and construction phases. The A10/A24 Availability Model project is one of these measures and is the first German public-private partnership (PPP) pilot project in which the BIM approach will be integrated from planning to execution and maintenance.

- Special features: Expansion to take place during ongoing road operation, BIM to run over entire life cycle (from planning and construction to operation and maintenance).

- Project: A10/A24 Availability Model; Havelland Autobahn

- Construction consortium: Wayss & Freytag Ingenieurbau AG and HABAU Hoch- und Tiefbau GmbH.

- Investment: €1.4 billion

- Completion: 2022

Open BIM for the Havelland Autobahn

The A10/A24 Autobahn is the main thoroughfare between Berlin and Hamburg. The infrastructure along the entire route can no longer keep up with the growing volume of traffic and the road surface is showing signs of wear.

The route will be widened and modernized to cover six lanes while traffic will continue to operate. The clients are the German federal government and the State of Brandenburg, represented by DEGES Deutsche Einheit Fernstraßenplanungs- und -bau GmbH. 2020 is the year earmarked in the German federal government's digitalization strategy by which it wants to make BIM the new standard for transport infrastructure projects and this section of the autobahn is among the BIM pilot projects that make up the government's 2020 road map.

This section of the Havelland Autobahn is also the first German PPP pilot project in which planning, design, construction and maintenance will be performed using BIM from a single source. Wayss & Freytag Ingenieurbau AG is responsible for the BIM management. The company, which is a subsidiary of the Royal BAM Group, is responsible for all planning and construction, and together with HABAU Hoch- und Tiefbaugesellschaft—forms the construction consortium.

The BIM contract covers a 5.5 km section of the autobahn. This section of the A24 will be comprehensively renovated and a hard shoulder will be added at various points between the Fehrbellin and Kremmen exits and will be opened to traffic when needed. Construction will include two rest and service areas, two traffic sign cantilevers, a replacement bridge, a noise barrier, and wildlife protection fences along the route.

The challenge: interfaces and data quality

A project of this magnitude involves not only a large number of planning specialists (bridge planners, route planners, operating technology planners, etc.), but also various software programs and systems that require a high degree of interoperability. It is important for all parties involved to develop a common standard, but such a standard does not yet exist in Germany.

This does not just apply to the planning phase: as a federal BIM pilot project, the application of BIM has been contractually stipulated for a 30-year maintenance period.

Daniel Krause, Head of Digital Construction at Wayss & Freytag, describes the project as “challenging and exciting,” explaining that the data collected during planning and construction will be used for subsequent maintenance and as such “requires defining data standards in advance to ensure the necessary data quality.”

Krause says that traditional project management is still light years away from being able to map on-going digital processes in a way that would require a piece of information to be entered into the system one time only in order to allow retrieval on multiple occasions and in various formats. The interface problems between the various tools have not yet been entirely solved.

The next hurdle was to ensure the quality of the data across the entire value chain.

“We have to be able to build on the data we receive from the client,” explains Krause. “We need to be able to determine quantities and base our calculations on this data.” Only then is it really possible to ensure the full potential of BIM: increased efficiency, higher quality, and reduced risk.

Krause identifies the final challenge not as planning complications but the obligatory change management: finding acceptance of BIM among the various stakeholders. “At the beginning of the project, we have to invest in order to implement the new processes throughout the entire project consortium,” he says. “This change process is going well, but it’s hard work.”

The Wayss & Freytag team is driving this transformation forward.

Our vision is to transform ourselves from a pure construction company into a company that uses, evaluates, and manages digital data along the entire value chain.

—Daniel Krause, Head of Digital Construction, Wayss & Freytag Ingenieurbau AG

The solution: digitalization reduces risks

The Wayss & Freytag engineers have a clear strategy to meet these challenges. “Our vision is to transform ourselves from a pure construction company into a company that uses, evaluates, and manages digital data along the entire value chain,” says Krause.

Using BIM creates a unique data source in accordance with the principle of a single source of truth (SSOT). This reduces the number of different information sources and also leads to fewer complications, shorter lead times, increased productivity, improved collaboration, higher quality, and lower costs.

Wayss & Freytag has demonstrated its innovative ability by taking things a step further. “For us, digitalization goes beyond the BIM road map,” says Krause. “It also means modernizing processes along the entire value chain. Where forms and printouts used to dominate, digital tools are now applied to improve processes, make things easier, reduce risk, and improve efficiency on the construction site, in the preparation of bids, and in everything we do,” he explains.

One of the contractual requirements in the BIM pilot project was the use of the open file formats *.ifc, and in some cases *. cpixml.

“Autodesk’s export function helped us transfer the data from the authoring program, and we were able to process it using our coordination software,” says Thomas Tschickardt, Digital Construction Manager at Wayss & Freytag.

Consistently digital implementation

Tschickardt believes that Autodesk is a good partner for the project team. “Autodesk covers nearly the entire value chain with its products,” says Tschickardt. “As well as ensuring the interoperability of its own products, it also allows and provides good solutions for interfaces to other products.”

The BIM 360 platform is used to digitalize construction management processes and in the future will replace paper-based processes as the standard in all projects, as well as allowing digital, mobile access in the cloud.

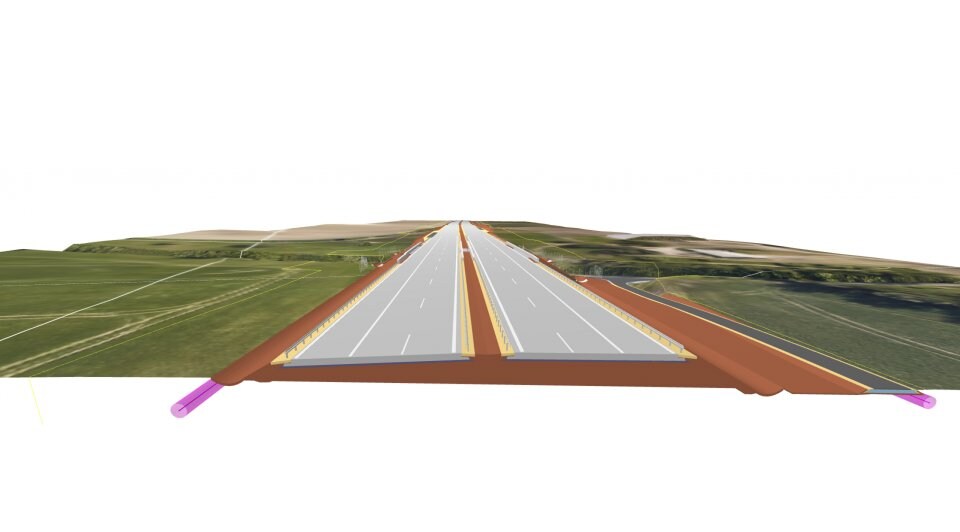

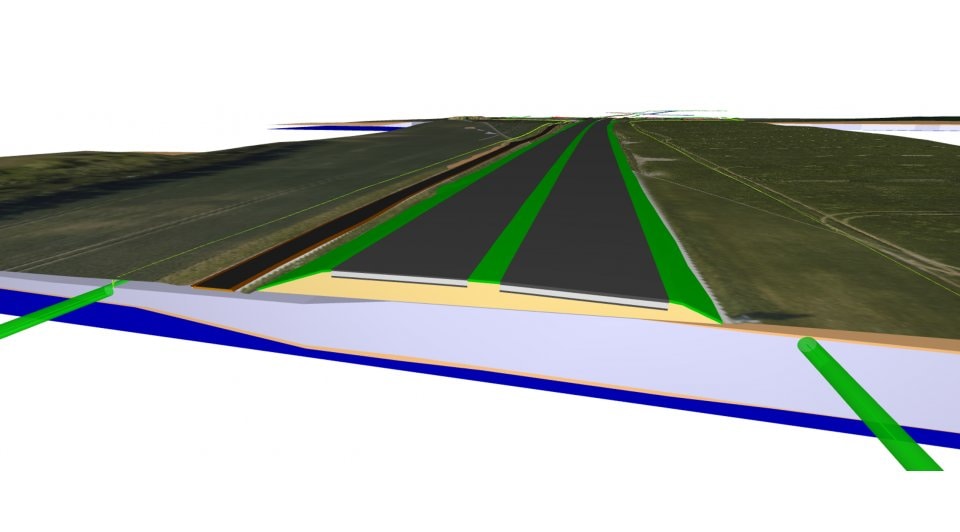

The context model, earthworks, subsoil (including soil layers and groundwater level), interim measurements of the road section, equipment for the temporary openings of the hard shoulder, landscaping, and the digital terrain model were designed in Civil 3D. The 3D model served as the basis for the development of project-specific use and was supplemented with geometric, topographic, and alphanumeric information by all the companies involved in the construction process.

The wildlife fences that run along the road were modeled by hand as a prototype for one area and then translated using Dynamo to create the entire remaining BIM section automatically, which saved the team an enormous amount of time.

The Autodesk Revit team used Dynamo to work on all the concrete components and elements for the bridges, which made it possible to identify the bridge/road interface (a critical area of the project) at an early stage. The visualizations created using 3ds Max are helpful for communicating with local residents.

The initial planning, realization, and maintenance of this section of road using BIM was supplemented by additional information, including time (4D) and cost (5D), in BIM 360 to allow rapid information recording, data management, and transparent communication. This made it possible to solve coordination problems at an early stage, minimize the risk of planning errors, and improve scheduling and cost planning.

The road operation data is then linked to the model in order to simulate and visualize the construction process. These visualizations can be used on the construction site as a tool or aid for construction and planning meetings, as well as for coordinating with the client or the companies involved in the construction process.

With BIM, we are creating a single source of truth. This leads to fewer complications, shorter lead times, increased productivity, improved cooperation, higher quality, and lower costs.

—Daniel Krause, Head of Digital Construction, Wayss & Freytag Ingenieurbau AG

Interoperability optimizes the construction process

Here’s a practical example: By considering the project over its entire life cycle, the site manager became involved in the planning meetings and provided input regarding the construction machinery required. This made it possible to clarify ahead of time that the installation of the planned sheet piling would require a different construction machine than was planned. Thanks to the common model that links all the data, this error was detected before construction began, saving avoidable costs.

The foreman then uses this model on the construction site. He enters the actual data from the schedule and the actual quantities directly from the construction site. These flow back into the daily construction report or to the engineers’ control system. This is typically how 5D is applied. All the data from the planning phase is supplemented by additional data from the construction phase. This provides a true 360-degree view of the entire project, which optimizes the construction process.

This was the experience of Tschickardt, who believes that “work has become more efficient while maintaining high quality and reducing risks across the projects.”

The basis for this is the Autodesk solution BIM 360, which enables digital defect management and ensures the availability of up-to-date digital plans for site managers on a tablet.

The great advantage of Autodesk for us is that its solutions cover the entire value chain and guarantee interoperability.

—Thomas Tschickardt, Digital Construction Manager, Wayss & Freytag Ingenieurbau AG

The result: successful BIM pilot in road construction

Wayss & Freytag’s strategy is paying off. On its journey from a pure construction company to a data-driven company, it has managed to model a successful BIM application over the entire life cycle of the A10/A24 Availability Model project.

Thanks to the coordination model, it was possible to visualize the construction sequence for the A10/A24 Availability Model as early as the planning phase.

“We've started to build even before we break ground,” says Tschickardt. This allows errors in the planning and construction process to be identified and rectified at an early stage.

The Wayss & Freytag team currently sees the added value in primarily qualitative terms. Tschickardt describes having BIM 360 for the entire section as “valuable for the entire team” and says that planning meetings can be “presented in a completely different way with 3D.” He explains that risk has been significantly minimized, especially for the BIM contract section. “We have complete cost transparency and see the impact of delays,” he says. “Thanks to 4D models, we can identify in advance that a pipeline runs underground and make plans to find an alternative solution rather than only discovering it on site.”

The quantitative advantages of BIM become immediately evident in defect management. Such management traditionally used Excel sheets and photos sent via e-mail. Thanks to the cloud-based solution, site managers can eliminate between five and eight times as many defects in a fraction of the time previously needed.

Open BIM and the use of digital solutions from planning and construction to maintenance has made this road construction pilot project a success.

“We’ve noticed increasing interest in using BIM for road construction over the entire life cycle,” says Krause. “The data and standards we’ve developed in this project make for an important foundation—cultural change in our industry has begun.”

BIM SOLUTIONS FOR ROADS AND HIGHWAYS

Create intelligent, structured data attached to a digital model to support each stage of a road or highway project.